It is no secret that outsourcing manufacturing to Asian countries is becoming increasingly difficult. As these countries develop stronger economies and their standards of living increase, their workers are demanding a raise in salary, making offshoring strategies more expensive. Other factors like sudden trade-wars, new taxes or unexpected threats like the COVID-19 epidemic, can multiply the challenges for manufacturing at a low price.

Recent developments in the field of automation, robotics, analytics, and the introduction of centralised cloud Material Requirements Planning (MRP) Software offer an attractive proposition for reshoring the supply chain for Australian manufacturers.

Besides the simplicity of manufacturing within the country, onshoring offers excellent local benefits too. Whilst some low skill jobs are eliminated by automation in the manufacturing process; high skilled opportunities are created in controlling and connecting intelligent machines, automated warehouses, and developing AI. The introduction of high skilled workers leads to an increase in the standard of living within the country.

Australian-made significantly preferred to Chinese-made. New research by Roy Morgan shows Australians are more likely to buy products across a wide range of industries if they know the product is made in Australia. Only a minority say... #ausmade #auspol https://t.co/TQNYdFGZOC pic.twitter.com/6ztBJfrec4

— Roy Morgan (@roymorganonline) October 29, 2019

Other benefits of reshoring include an upturn in the quality of the manufactured products as tighter control of the supply chain network can increase the final quality of the products. Besides, as more than 80% of Australians prefer products made within our country, manufacturers have another strong reason to build their products onshore.

A Centralised IoT Platform for Cutting-Edge Technologies

Most manufacturers are already using IoT to a limited extent. However, some have seen the signs and taken it to the next level, with a number of sensors and through APIs, they are leveraging the advantages of monitoring production, automated distribution of products, allocation of resources and even tracking of logistical supply.

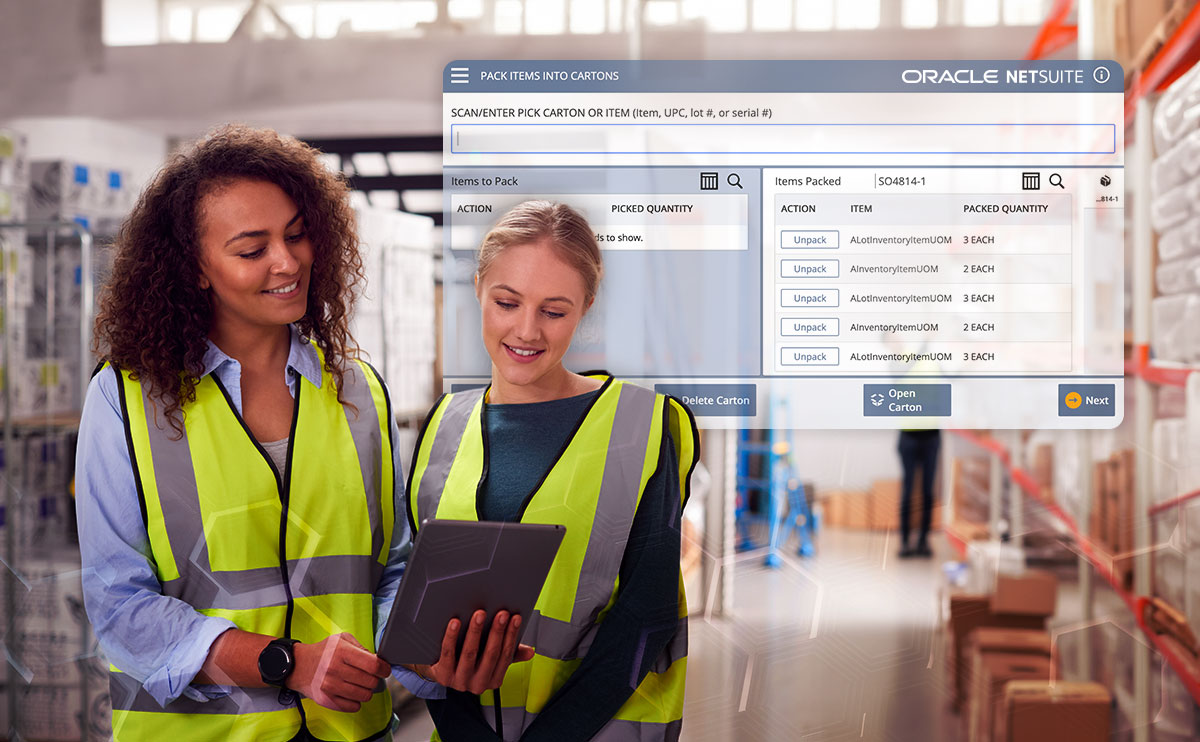

Artificial intelligence, 3D printing and all the innovation that comes with adopting Factory 4.0 will make it much easier to manufacture. However, controlling these hardware and intelligent gadgets in a centralised platform can be a difficult task. This is where an IoT based ERP like NetSuite with a robust true-cloud API comes in handy.

NetSuite helps with the adoption of new supply chain IoT technology, by connecting all data from the sensors and peripherals into a centralised platform where all data from CRM, finances, payroll and inventory live. This data consolidation enables better reporting, advanced dashboards and a more informed decision-making process.

Easy to Scale Whenever Needed

MRP software has definitely evolved over time. We’ve come a long way from an era where every business had to use the same basic boxed software without customisation passing through a time where platforms could have so many variations that they felt into over-configuration and never-ending installation processes. Nowadays, however, with the evolution of SaaS, businesses can gradually enable modules on-demand as they grow.

This is a big advantage for small and medium-sized enterprises where results need to be quick while adhering to strict budgets. All along, growth targets need to be achieved. With and ERP that is MRP enabled like NetSuite, all operations can be managed centrally through the cloud and scaling up any area of the business is quickly addressed when the situation demands it.

Why is scalability important?

In a world where disruptive technology happens more often, profitability hinges on the ability to adapt quickly to new platforms and trends. Investing in platforms that can do virtually everything can represent a significant expense, and they usually go underutilised, whilst with modular software, you pay only the modules that you use and the investment required is drastically reduced.

Better Production Management

One of the main aims of Factory 4.0 is to reduce waste in manufacturing, and this includes reducing the wastage of time on unnecessary tasks. Maximum utilisation of time can only be possible when workflows go according to strict plans and where jobs that add no value can be eliminated easily.

With the help of NetSuite, you can effortlessly plan all the raw materials that are needed for production, place your inventory in strategic positions and assign work timings for employees. Moreover, you can also control the workstations where production will be taking place. All this can be done to deliver goods on-time in the right quantity and quality.

Stockpiling Inventory to Address Demand

When a company decides to reshore their operations, inventory can be maintained in bulk as the production volume goes up. It often happens that there is a shift in focus from current sales to future sales. This leads to stockpiling of the inventory, and if it’s not managed correctly, it can lead to a supply chain disaster.

NetSuite is built with a number of tools and features that facilitate inventory management, from tracking inventory in various locations to keeping stock of safety inventory. Furthermore, you can plan the demand and distribution needed to meet it. NetSuite clearly suggests when and where to restock so that your decision making can be used for something more substantial.

Transform #Manufacturing from Offshoring to Rightshoring in 3 Easy Steps: https://t.co/d8nLNfxz8H pic.twitter.com/he57qFAmlE

— AUS Manufacturing (@AustralianM) January 23, 2020

Onshoring poses a bright future for Australian manufacturers.

We can say that the reshoring of manufacturing hasn’t looked this promising in the last two decades. Moreover, by adopting technologies related to factory 4.0, the possibilities will only get better and better.

One thing is clear: businesses that fail to adopt these changes are going to perish. Emerging technology like 3D metal printing, artificial intelligence, automation, and robotics will make your competitors produce goods of better quality locally and at a rapid pace.

NetSuite is a one-stop solution for all manufacturing challenges. By providing end-to-end services ranging from financials to warehouse and fulfilment, this best-in-class ERP software can help you embrace the new manufacturing era.

Need a specialist’s free advice?

Feel free to call an expert in Automation in the Manufacturing Floor with NetSuite Enterprise Resource Planning. Find out how cloud-based technology can make your manufacturing business an onshored beast.

References

- Transform Manufacturing from Offshoring to Rightshoring in 3 Easy Steps

- Australian Manufacturing Technology Magazine (AMT) February/March 2020

- Government must develop plan to support manufacturing jobs

- Technology brings new hope to Australia’s manufacturing sector

- NetSuite Planning and Scheduling

- NetSuite Inventory Management